Fabric printing is basically the process of applying different coloured designs, patterns, and motifs onto fabric. Creating sharply defined patterns and imprinting them onto the fabrics is not a cakewalk. Let’s discuss how some of the printing methods are carried out and how they have changed the way we look at the fashion industry.

Types of printing methods

-

Stamp Printing

Stamp printing is the process where they make use of stamps to imprint on the fabric. It is quite simple and pretty much similar to making potato stamps that we used to do as kids to create beautiful paintings. Stamp printing is where they take a design or customise one, cut it into the stamp, dip it into the ink and transfer it from the stamp onto your textile, using pressure.

-

Transfer Printing

Another fabric printing method is transfer printing, made using transfer paper. Transfer paper is available in most stationery stores and even in some supermarkets. It’s a DIY printing method wherein you can use a standard household printer when you are looking to print your own design onto the transfer paper, which is then printed onto the chosen fabric using a standard household steam iron. This method can be more high-end and upscaled to be done professionally on larger runs, but this method is likely to leave a shiny film or surface texture on the fabrics. However, note that it is not a permanent method of fabric printing; with time and after a number of washes, it can peel, crack or fade.

-

Dye Sublimation

Dye sublimation is a multi-step process producing some of the best results when talking about fabric printing. In this process, they take a thermal transfer paper that goes by the name of dye sublimation paper, which is used to imprint on the fabric. In order to permanently bond the inks to the fabric’s fibres, you will need both heat and pressure silk scarves. The method ensures that your fabric is left as soft as it was before it was printed. The deep infusion technique spikes specialist water-based inks into the fabrics, making your print a permanent one. Dye sublimation works perfectly for the intricate details and addition of colours in the design.

People choose dye sublimation for its ability to create amazing image reproduction that lasts for life; it leaves no texture or residue on the fabric after printing. The dye sublimation process is eco-friendly and done with water-based inks that do not fade or peel. It is considered suitable for all-size print runs.

The downside to dye sublimation is that it can only be used on poly textiles and not on natural fabrics. It also requires specialist equipment and dyes, making it a more expensive method of printing, plus it requires in-depth extra knowledge and experience.

-

Reactive Printing

Another form of heat-activated fabric printing is reactive printing. It requires the Pre-coating of the fabrics using a binder and printing additive to imprint the fabric. It uses wax or dye to print onto the fabric, and the heat reaction permanently bonds the image to the chosen fabric. Basically, it is a lot similar to coating the fabric with design and then steaming it, resulting in a reaction that bonds the design to the material.

Reactive printing works amazingly well on natural fabrics, giving the textile incredible colour vibrancy. The downside to this printing method is that it requires a lot of pre-treatment and post-treatment, which makes it a hard one to carry out; plus, when it comes to price, it may not be the most cost-effective method of printing.

-

Pigment Printing

Pigment printing is one of the most popular and widely-adapted printing techniques for cellulose fibres. It is one such printing method that is used on both natural fabrics and synthetic fabrics, which makes it quite versatile. It is a confined printing technique with the application of a lot of dyes to the part of the fabric where you want your design to show. Doing it over and over slowly builds up its colour. The prints are carried out using bright and permanent colours. They are easy to do and cost-effective, with no high-end machinery required for the same.

-

Digital textile Printing

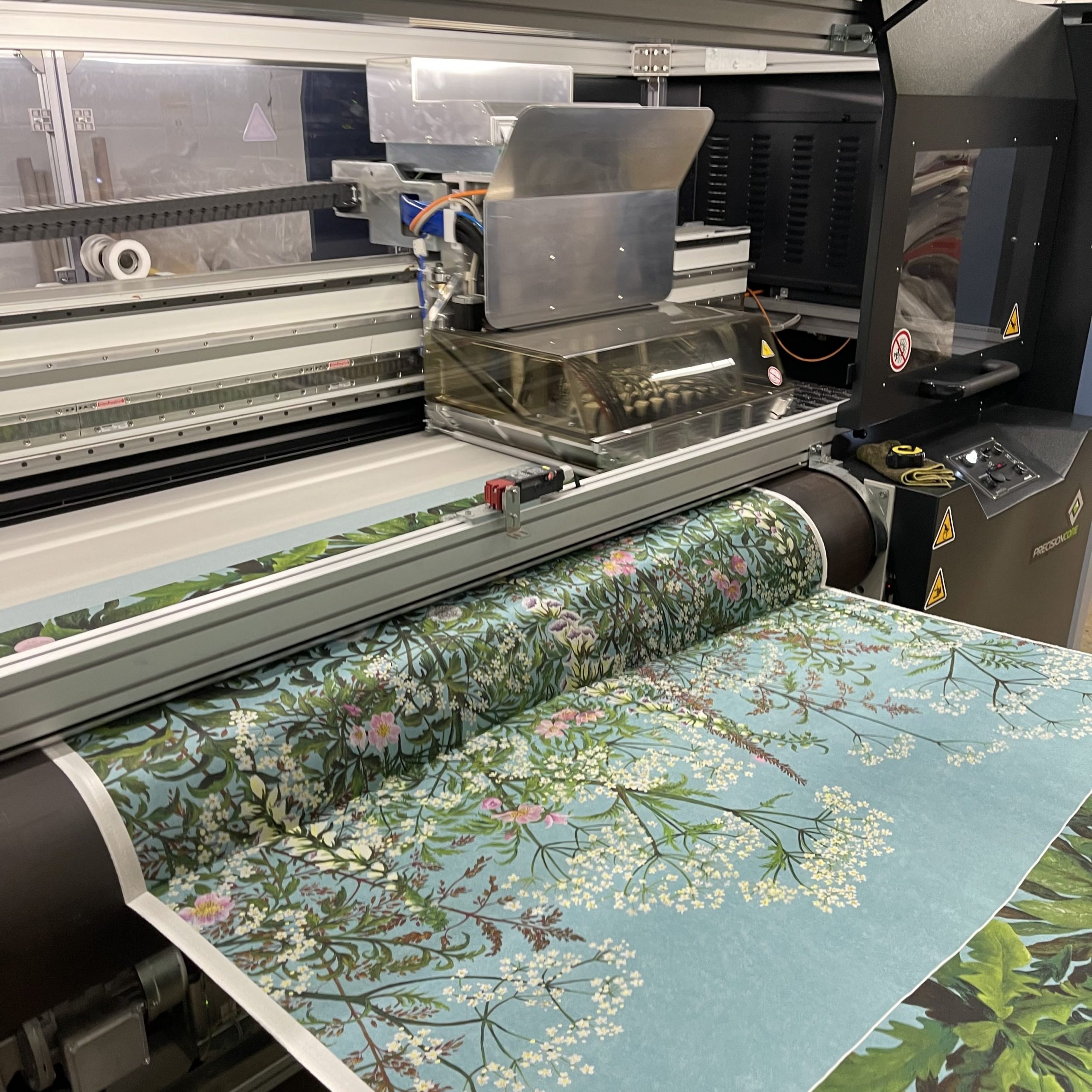

Digital printing on fabric has levelled up the entire game for the fashion industry; from getting your favourite prints easily on your clothes to even sticking your puppy’s picture onto your t-shirt, digital printing has taken printing to the next level. The inkjet-based printers make it possible. The printer feeds a roll of fabric through a large-format inkjet printer and imprints the design directly onto the fabric.

People these days are turning to sustainable ways of living, extending this habit even to clothes; they are woke and understand how much waste unsustainable clothing produces. Be it printed t-shirts, printed on scarves, printed on pants or even home curtains and upholstery, people are highly impressed by how digital printing is making it all possible, sustainable and at the same time stylish.

Looking for personalised prints on your clothing? Look no further than Forest Digital.

At forest digital, we are pioneering the world of digital printing with decades of experience now. Offering our clients bespoke creative guidance and in-depth knowledge of a large number of fabric types alongside state-of-the-art digital fabric printing.